Navigating risk from start to finish results in a successful project completed on time and on budget.

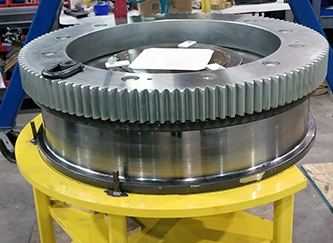

Fabrication & Quality Control

Supply Management

Uni-Systems Engineering maintains long-term business relationships with fabrication facilities and machine shops that share our commitment to quality, value, and on-time performance. Uni has expertise and many years of experience in managing these vendors and working closely with them to deliver quality parts and assemblies that meet or exceed our customers’ requirements.

Quality Control

We maintain a robust quality management system. The program’s policies, procedures, and documentation ensure quality, identification, and traceability of products manufactured by Uni-Systems Engineering and our subcontractors. Most of our projects require dimensional reports, material certifications and tracing, rigorous weld inspections, plating and coating certifications, and other fabrication quality assurance and documentation. Similarly, our assembly and testing work is tracked and documented for quality and conformity.

Shop Drawing and Detailing

Uni-Systems Engineering’s engineers and designers work with 3D CAD models to fully detail components and systems. Our extensive experience in equipment fabrication and delivery give us a strong perspective on proper part and assembly design and detailing. Our shop drawings are complete and detailed with all information required for fabrication by a 3rd party shop.

We develop project-specific solutions to complex and unprecedented engineering challenges.

Contact us for a a customized solution for your project.