The Uni-Systems Engineering team is comprised of structural, mechanical, and electrical engineers with experience at the highest organizational levels on the turnkey delivery of some of the world’s largest and most versatile cranes.

Crane Design and New Construction

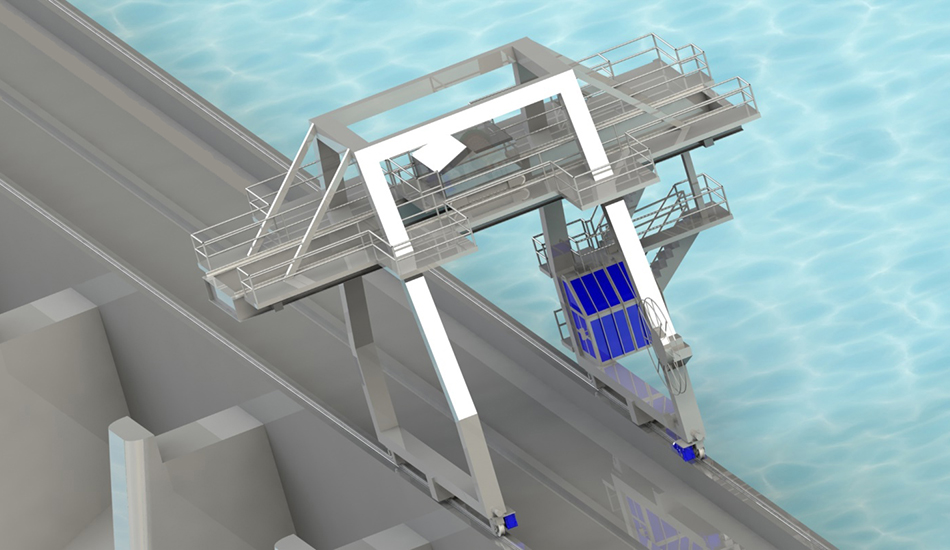

Turnkey Solutions for Custom Heavy-Lift and Duty Cycle Cranes

Our engineers have designed, tested, and commissioned over 125 cranes and custom hoist systems through prior experience with AmClyde. Equipment ranged in size from 2 metric tons to 5,000 metric tons for both domestic and international customers, and met demanding project-specific performance requirements. Our resume includes the following:

- Designs conforming to ABS (American Bureau of Shipping), LR (Lloyds Register), API (American Petroleum Institute) Specification 2C, CMAA (Crane Manufacturers Association of America) 70, AIST (American Institute of Steel and Technology) Technical Report #6, DNV, GL, and OSHA

- Crane styles including gantry, derrick, stiffleg, portal, marine, offshore, barge-mounted, dredge, stevedoring, pedestal, kingpost, fully revolving, and level-luffing

- Hoist systems including rotary winches, rotary hoists, linear winches, wildcat/windlass systems, and traction winches

Leveraging Uni-Systems Engineering crane expertise, extensive network of high-quality suppliers, and experienced installation team, we can meet your project-specific requirements for the turnkey delivery of the largest and most demanding crane applications in the world.